Rear Shock And Spring Replacement

Henry Fok, photos by Larry Karpman

This task is not very hard. You can easily do this in your driveway

in under two hours per side. You do not have to remove the subframe,

and there is no imminent danger in removing the springs from the car

as with the front springs. Since the procedure is much the same

between these two tasks, they are presented together.

The car in these pictures is Larry Karpman's 1987 XJ6 VdP. The

ugly galoot in the pictures is yours truly. This information applies

to the Series III only - other Series are similar, but I can't

guarantee that they'll be identical.

For this task, you will need a ratchet, a selection of SAE sockets

and wrenches, a hammer, and a spring compressor (AutoZone rents a

decent one, and that unit is pictured here.)

You may click on any picture to see a much larger version. This

FAQ is not a substitute for a workshop manual. It is intended as a

supplement, to give you some idea of what things look like and what

the manual is talking about. Therefore, not all the details will be

given.

***

Loosen the lug nuts on the appropriate wheel. Jack the car up and

support it properly. Instructions on how to do this are elsewhere in

the FAQ's, so I will not reprise that information here.

Remove the wheel. What you see should look something like the

following picture.

You see the shock/spring assemblies clearly visible. Note the

radius arm extending from the main chassis to the rear hub

assembly.

Remove the rear nut from the crossbolt. This is what the lower

eyelets of the shocks attach to. Tap the bolt out rearwards, gently.

Side in picture is INCORRECT, and was done for photo purposes.

Wrong side nut was removed to indicate which bolt! Tap out from rear

(opposite) side!

The shock assemblies are now held on by one bolt, at the top of

each shock. Remove this bolt, paying attention to how the washers go

in place. The front bolt will have a washer attached to something by

a spring. Be careful of this, and remember where this goes.

Upon removal of this bolt, washers and nut, the shock and spring

assemblies will no longer be attached from the car. Remove them.

Don't worry about mixing them up - they're identical. If you are (for

some reason) replacing the shocks without replacing the springs or

vice versa, attach the spring compressor to tan assembly and follow

the directions on how to secure it to the spring. If you are

replacing both with OEM units, toss the old assemblies into your

scrap bin - you do not need to strip the hardware from the old units.

Attach the spring compressor to the new spring per the directions.

Compress the spring.

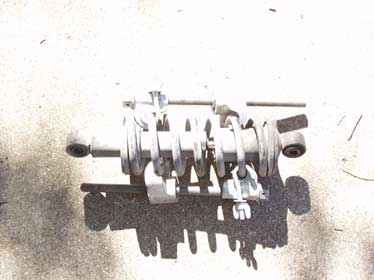

Below is a picture of the top of the shock and spring assembly.

Note that the spring plate is held to the shock body by these two

collets. If you are separating the old assembly, you will have to

compress the spring to the point where the place is below these

collets and you can pry them out of their channel in the shock. Then,

you can remove the plate and spring off the shock body. If you are

replacing the entire assembly (or have completed the prior step if

replacing only one element), you will need to compress the spring to

the point where you can put the plate on, fit the collets in their

slot, and then decompress the spring, allowing the spring's pressure

to hold the collets and plate in place. Note how everything is

assembled here. (Towel is to stop freshly oiled air tool from

spraying oil everywhere.)

This is about what it should look like when the tension is

released. The collets should be seated in their groove on the shock

fully. There will be a gap between the collet ends; arrange this as

seems most aesthetically pleasing to you.

Now is also a good time to replace your radius arm bushings - but

that's covered elsewhere. Greasing the now easily accessible grease

points is a *really* good idea at this time, too. Reinstall the

assemblies by their upper eyelets. Remember to assemble the washers

in the order that you removed them. (We broke the whip hose when

doing this shoot. It is not recommended that you use air tools

without a whip hose.)

You may have to twist the lower shock eyelets around to make them

line up correctly. Reinsert the crossbolt, tighten down the nut, and

you're about done.

The rest, as they say, is the reverse of disassembly.