JEC Glasgow Region

Home : Members profile : Projects: For Sale: Contact : News

Original Barratt advert |

S Type steering conversion - by Alastair Reynolds

I Have been the owner of an S Type now for the last 3 years (9000 miles).

When I got the car the steering was to be honest a bit flakey. I replaced the

track rod ends (4 off) and the idler and spigot bushes. Jamie Gibbon in Glasgow

shimmed the power box to something like normal. The steering was ok but not

fantastic, not exactly positive but at least not dangerously vague like before.

These renovations kept me going for two years but in a moment of madness in an

attempt to replace a leaking steering pump with a second hand pump I test drove

the result only to find that after a few miles the pressure limiting valve stuck

and all power to the steering box was lost. The process of returning home with

no hydraulic steering pressure was enough to completely stuff the free play in

the box to an unacceptable level again.

Worse than that Jamie from Glasgow did not recommend shimming the box again

in case the steering seized in extreme conditions of lock and temperature. I

spent the winter of 95 looking for a second hand box in reasonable condition,

this proved to be a fruitless task, the closest I came was the temporary

purchase of a reconditioned box from FB components. This turned out to be the

wrong type.

At this time I became more interested in the various conversion kits to

modern rack and pinion. There are three kits on offer Ken Jenkins, Barratts and

a company called Classic Jaguar Spares. The Barratts kit is manufactured by

Vicarage. In fact Anthony Parkinson run's Vicarage's US marketing operation and

is a very active participant on the Jaguar Lovers Internet mailing list. I have

to state I did not want to do this conversion, I dearly wanted to keep the car

original. If the cost of keeping the car original was really poor steering then

that was a price to high. Either upgrade the steering or sell the car that was

the choice. I decided to keep the car.

|

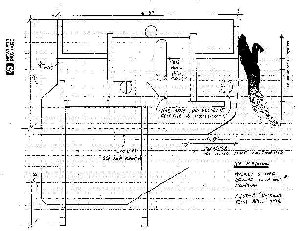

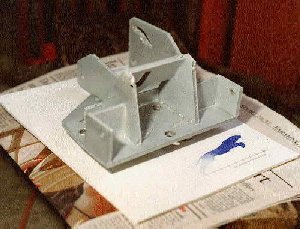

New bracket design front

New bracket design side view |

For almost one reason I chose to pursue the Barratts/ Vicarage approach,

they were also the most responsive to my questions. The reason I was keen on the

Vicarage kit was the treatment of the power assisted steering (PAS) pump,

located below the generator away from the roasting manifolds and retaining the

original fan belt and pulley system.

The down side is that they had never fitted the kit to an S Type. I looked

closely at the manuals and the chassis of both cars, they looked very similar to

me. Barratts (Richard Darcy) were very keen to sell me a kit but initially could

not give me a guarantee that the kit would fit my S Type. As time passed I kept

phoning Richard up asking if they had any more information about fitting their

kit to an S Type. He eventually came up with an offer I could not refuse (I

guess he figured it was the lessor of two evils, lets face it I was not for

giving in). They would sell me a kit and if I had any problems they would fix

them no matter what the problems were. They would even fit the kit for free if I

took the car to them in Shropshire, if I chose to fit it myself then if I got

stuck then if I got the car to them they would still fit the kit for free

assuming I had not caused any damage in the process.

Being a Jag enthusiast of course I was not keen to let someone else have the

fun of converting my S Type for me. I elected to buy the kit and fit it myself

despite the kind offers of Barratts. Armed with the assurances from Barratts the

distributors and Vicarage the manufacturers I proceeded carefully.

The kit arrived in two days, that is where the fun began (I do not mean that

in a negative sense), the rack fitted well enough, some minor tolerance problems

with the left mounting bracket (bolt alignment) I suspect the Jag chassis was

not manufactured to the same tight tolerance as the Vicarage bracket, some

obround holes would be helpful. The main problem is with the clearance between

the knuckle joint connecting the lower steering column to the new rack and the

chassis. The lip on the corner of the chassis fouls the new joint (see photo). I

was being sent by my employers on a business trip on the 1st April 96 to

Vancouver, so I arranged for Alistair Buxton from Thorns Garage to modify the

chassis, I was not happy with just bending the lip up, as recommended on the MK2

conversion.

|

Chassis before modification

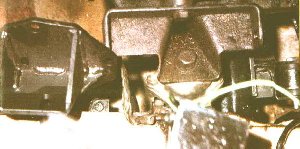

Original Vicarage PAS and engine mounting |

The subframe on an S Type and MK2 are mounted on rubber blocks which

move around while cornering. The S Type may be more of a problem in this area. I

wanted at least half an inch clearance. Just bending up the top lip would only

give an eighth at most.

On my Return from Vancouver I found the welding had indeed been done (see

photo), Alistair had left plenty of room for the new steering joint, he had even

reconnected the lower column for me. The next step was to connect the pump, no

it did not fit, even although the chassis dimensions according to the Service

Manuals look identical at the front between the MK2 and S Type. I wrote an

e-mail to Anthony Parkinson in the US and he said to contact Malclom at the

factory in England. Malcolm was extremely helpful, and extended the offer again

to bring the car to him and he would fix the problems.

I do not give up that easily, there were two basic problems, 1) The engine

stabiliser brackets on the sub-frame denied access to the rear of the PAS pump

for the hydraulic pipes. 2) The PAS pump fouled the engine mounting in a major

way so as not to be adjustable for it's drive belt.

I tackled the stabiliser bracket by removal, as the bracket by 1966 was no

longer used. This unfortunately required the removal of the sub-frame first.

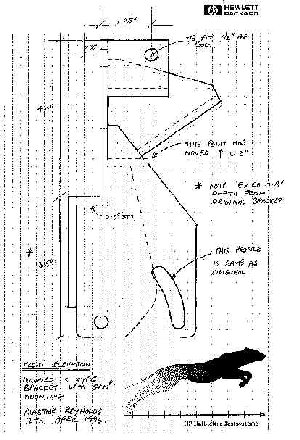

The other problem required a new bracket. I phoned Malcolm again with a new

suggestion, how about me sending him a design for a new bracket and they could

make it up. To my surprise

Malcolm said yes, I sketched a quick drawing and FAXed it to them for

comment. To my surprise they proceeded to make the part. In the interim I found

another problem with the conversion. Vicarage designed their kit to integrate

the lower engine mounting and the PAS pump into one bracket. The MK2 conversion

remounts the Generator (if not already mounted) on a separate bracket (not

supplied 15 pounds) fixed above the engine mounting. The original S Type bracket

has the engine mounting and Generator mounting integrated. |

Chassis modified to take new lower steering

column

New bracket in cardboard mock-up

|

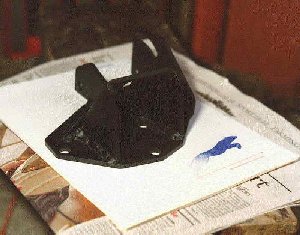

The bracket Barratts

had supplied refitting the Genny above the engine mounting did not fit my S Type

in two key respects. The problem is the air intake on an S Type is located next

to the Genny, extending the adjustment for the Genny location would have

violated that space (assuming the fan belt remains the same length).

The

alternative would have been a shorter Fan belt (why have another non standard

arrangement if you can avoid it). The other problem is that the bracket supplied

by Barratts was 1/4 inch too short, this was easily fixed with a spacer, again

what a guddle ( a well known Scottish term for a bodge).

I phoned Malcolm at the factory and explained the new problems, as ever he

could not have been more helpful he put me in touch with Peter who was making my

bracket. I agreed to send a new set of drawings after I modelled the new set up

in foam board so as to get some check on my design. Foam board is one of these

modern materials that professional model makers use for fabricating look-a-like

models of the finished product. I choose some 3/16 thick the same as the

mounting bracket for the steering pump. After three attempts I eventually had a

design that worked, the foam board is so strong you could even mount the pump in

it's new position and check the clearances. The bracket design (including

Generator mounting now integrated) was FAXed to Malcolm on the following Monday

and to my utter astonishment the bracket was ready by Tuesday afternoon. This

buy the way is no ordinary bracket. For a start it is made of 3/16 inch mild

steel with no fewer than 12 parts before welding. The parts themselves were not

a simple shape either. Those chaps at Vicarage certainly appear to know what

they are about. Malcolm said ``he had never seen a bracket like it, mountings

for everything in all directions''. The bracket is now fitted it is as designed the best compromise in all

directions. Best clearance between PAS pump and chassis, best clearance between

pump and engine mounting, best clearance between return pipe and sub frame.

|

New double crank shaft pully

New PAS pump in position

|

There is only one problem, the belt (775mm x 9.5mm) does not fit (too loose,

belt slips on full lock). The next size down (765mm x 9.5) it too tight to go on

the pullys. The remedy, you gess it right first time, phone Malcolm. He suggests

making a larger pully on the PAS pump which was duely fitted.

Conclusion The car is now roadworthy for the 96 season after many

hours and with the MOT just passed. Sure it took much longer than anticipated (4

Days over a month), but is that not what Jags are all about. I have to pay

tribute to the backup that I got from Vicarage this was probably influenced in

no small way by Anthony Parkinson. And also the Skill and judgment that Richard

at Barratts showed in striking the original deal. I am in no way connected with

Barratts or Vicarage other than by virtue of the WWW. I must also thank Alistair

Buxton of Thorns Garage for the excellent welding on the chassis. I can honestly

say that the experience has been well worth while from all sorts of angles. And

last but not least Peter at Vicarage who welded up the bracket.

My steering is now a miracle of modern engineering, I have driven it

aggressively and I can honestly say there is no hint of bump steer problems so

as I can detect. To be honest that was my biggest worry. I checked the steering

geometry on axle stands (off load) and on the ramp ( on load) the geometry as

far as I could tell remained the same. That is measuring the tracking in both

positions I think I would have detected if there was a problem. I guess there

could be a problem with the geometry while cornering, but aggressive driving so

far has revealed no nasty behaviour.

I enjoyed the problem solving, especially when I now know the people at

Vicarage who have renewed my faith in classic car business. It is nice to talk

to people who are interested in your problems after they have collected your

money. Vicarage does now have a solution for the S Type and my testimonial as to

their organisation.

|

Original Jaguar engine mounting

New PAS rack mounted under engine

|

I can show by this article that you can with some effort and very little

skill fit modern steering properly to an S Type with good backup from a

professional organisation. If I was to do the job again I am sure it would take

half the time. After all my estimates include time to design a new bracket, that

was the only skilled part of the job.

Health Check

- Loosen steering column so as to release lower steering column.

- Disconnect old steering hardware

- Mount new steering rack ( 4 bolts).

- Remove carburetters for access to chassis for welding. You can do this

without removing the carbs if you have a pit or a ramp.

- Modify chassis (see photograph) to allow plenty of room for knuckle joint

at bottom of lower steering column.

- Remove radiator to gain access to engine pulley.

- Remove Generator and bottom engine pulley.

- Fit new bottom engine pulley

- Remove sub frame and steering to grind off stabiliser bracket. Remove

bracket. (MK2 does not have this bracket).

- Refit subframe

- Remove right hand engine mounting

- Fit mounting bracket for Generator, PAS pump and engine mounting removed in

8.

- Refit all the hardware that is not already replaced (e.g. Carburetters,

radiator, Generator etc.).

- Set up steering geometry, any good service manual with rack and pinion

steering will tell you how to do this.

Note:- When considering the cost of this upgrade remember all the parts you

come across that may need replacing because they are old or worn out

|

The necessary MOT inspection

New horn location offside (UK)

|

If you don't feel up to the job (Being an amateur the job took me 4 days

over a Month) phone Malcolm at the factory, I am sure they can fit it for you

for a small fee.

Alastair Reynolds 1996

|

Created: 1996

Last Updated: 14th February 1997, 11:21 PM

|