Body jigs

Body Jigs

New content added 11th April 1999 From Wray Schelin

I'm sending you three jpegs for the webpage. The first is a photo of

the 120 FHC that Bob Lockas ( a XK Lovers list member from KS) is

restoring.

He had sent me some photos of his car, so as to show me what

sheetmetal he was missing and would probably need. Apon receiving the

photos I noticed what a nice design that he had come up with for his

body gig.He wanted something that would have utility beyond just his XK

120, so he designed the gig to be essentially infinately adaptable and

also something that could be collapsable when not needed, and to boot

inexpensive, strong, and allow you to really have good working room

around and underneath the car. It will accept just about any car

providing you adjust or change the length of the support arms, and the

location of the supports themselves, which are slide adjustable, this

allows any pickup point to be matched on a car body.

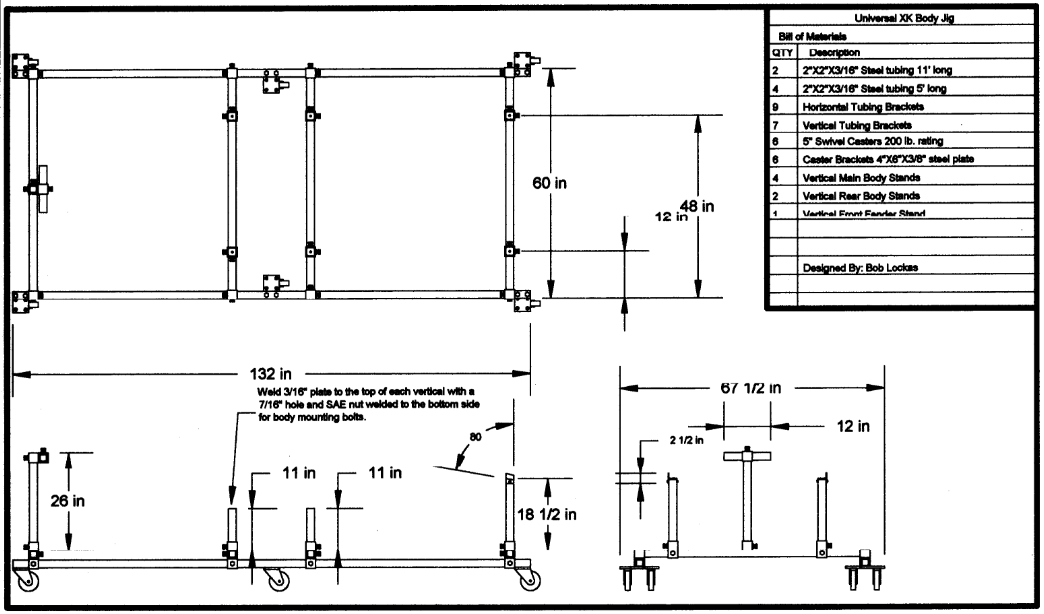

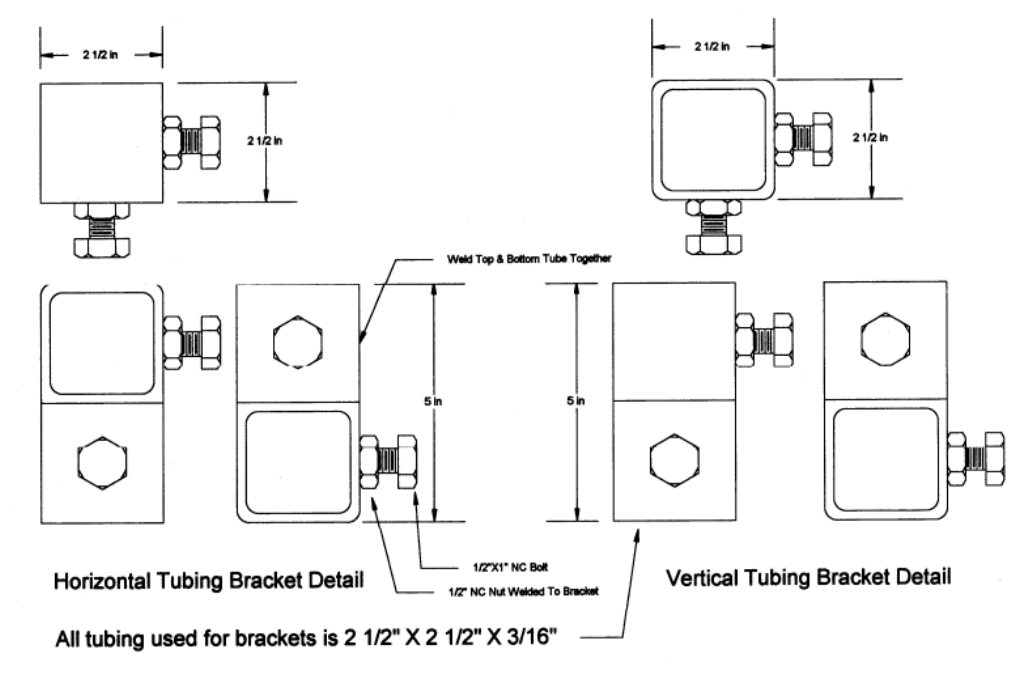

I asked Bob if he would allow his design to be posted on the XK Lovers webpage so that

everyone would get a chance to see a well made gig, something they

might consider to build themselves. Bob also had his son send me some

drawings of the design showing all of the necessary dimensions and list

of materials to build the gig. Bob mentioned that if anyone wanted a gig

made just like his and they didn't have time to do it themselves he

would consider making copies of it. You can contact Bob Lockas at:

lockas@swko.net

Hi all, I've recently recieved a catalogue from Guy Broad and in one of the

glossy brochures that came with it, showed an XK120 off its chassie and on

a jig. Does anyone know the dimensions (mounting positions, heights, etc)

of that type of jig? ...I would like to build one for my 120 as I feel the

body will be off the chassie for a while and it will make the restoration

much easier. Thanks - Gary Coorino

Gary: I second your request. Some months ago I made the same request to

this group, without a response. I plan to build one sometime this summer

for my xk120 FHC. If it works well, I will share it with the group. - Carl

Hanson

To all... is the notion of a travelling universal FHC jig too impractical?

Have any of you tried the rolling rigs which attaches to the axle stubs and

"alledgedly" allows you to position the body at any angle from horizontal

to vertical with only a few pounds of lifting force. My back and overhead

welding skills both think the rollin' idea is good; but what say ye?

Regards - Klaus Nielsen

Klaus: I have seen the "tilters" and they do work. One on the best ones is

made in Germany and distributed here on the West Coast US By MnG (Made in

Germany) PO Box 181281, Coronado Ca. Tel 619 437 7001. While they could be

purchased direct from the manufacturer in Germany at a reduced price, the

hassle of importation has to be considered. (No, I have no interest in the

business). The literature shows a seductively simple device that tempted me

to consider fabricating my own except for the consideration of my poor

welding skills would give me ulcers every side I had a beloved car on its

side! - Regards, Bruce Baysinger

Bruce, I have the same welding reservations, which of course prompts the

thought of just having the "curvy" pieces rolled and bolting the assy

together. Bolting would sure ease shipping and sharing of such a beast. Do

you own sketches sufficing for reverse engineering. Regards - Klaus Nielsen

Klaus: I had drafted up the rolled pipe and plate sketches and gave them to

a friend of mine about a year ago to have them fabricated "under the table"

at his place of employment and have not seen them since. Thanks for the

reminder. If I can get them back I'll send you a copy. - Bruce Baysinger

My XK-140 OTS body is currently resting on a truss-type frame with castor

wheels (hopefully not for much longer). I'll get the dimensions the next

time that I visit the body shop. It is, however, a pretty simple structure,

since the body isn't all that heavy. Make sure that the framework supports

the body mount hardpoints, but don't worry too much about the front and

rear body overhang. With the OTS, at least, you must strengthen the door

opening by mounting a steel bar that runs from the scuttle to aft of the

door. I mounted the bar at the hood (soft top) pivot and at a instrument

panel support. - Regards, Mike Carpenter

Listers: I am going to need a body jig for a 120 ots in Chicago around

June, if anyone would like to rent one to me that would be fine. If not I

would take on the task of having it made. 1) I really don't have any

storage space for this once it is built, again any ideas ? 2) Does anyone

have a bare 120 frame that I can take measurements off of ? OR would anyone

be willing to take the time to provide me with measurements and demensions

? 3) Would anyone be interested in sharing the cost ? I feel that a large

diameter tubing, about 3 inches, with "outriggers" to support the main part

of the body undercarrage with smaller tubing as a substructure to hold the

cowl etc. would be the way to go. 6 to 10" casters would make it roll over

any surface. All turnable, 2 with brakes. Is this overkill or do you think

it will not be sturdy enough ? PLEASE GIVE THOUGHTS AND OPINIONS. Any

ideas.......????? - "Midget" Susan (Susan Hedman)

Klaus: Travelling in what way? Like use it for awhile and send it to

someone else? or something on wheels? The rolling jig you mention would

be useful for body-on-frame repairs, but I think both Gary and I are

looking for a jig that will hold the body together while we send it to the

paint shop off the frame. - Carl Hanson

gary - you dont need to know the dimensions of a chassis jig, mount it off

your body points make it out of 2" x 2" rhs steel and you have a replica

xk120 chassis at least as far as the mount points (and thats all that

matters) is concerned. Works for any car you like. - Peter Hitchin

To all, re the discussion on body jig's. I have one available but in the

Netherlands, Also: It is a rather large piece, about 2 by 1 meters and

heavy It was purpose made based on a crude general jig. If somebody is

interested, Please let me know. Also I am about to put the newly cut front

windows in my 120 FHC. This seems a difficult job for at least two persons.

Any tips available? - Duco Avis

To all XK 120-140-150 Jag Lovers needing a body jig, I have one that is

adjustable and works very well. It is on caster wheels that make it

portable. It holds the body in a rigid position so if you are replacing

the sill or major parts and panels, it will hold the car correctly. Give a

mail address and I'll send a drawing and picture. Still need help on my

XK120M Fixed Head Coupe Parcel Box and partition behind box and trunk

area. Can anyone help locating these parts in the USA? The information on

my 1954 XK120M Fixed Head Coupe: Chassis #680147. Engine #W6204-8. Gear

Box #JL13354. Body #J2156. E-Mail address lockas@swdtimes.com - Bob

Lockas

Hi everybody, Well from the email regarding a body jig it is apparent that

several people have a need for such a device. Whether a jig is manufactured

for the members and made available, say for a rental fee, is to be debated

but the problem arises as to how long one person can have it while others

also have a need ....it can get messy. Also the type of jig would be

important, a simple device may suffice for body off painting but a more

complex and sturdy device would be required to do major body work, then

transporting such a device could be costly and components can go

missing....it get messier. I'd sooner build my own, and as I have major

work ahead, then if it were able to support the body correctly while this

type of work were carried out then the better. At the end of the project it

could then be sold to another XK restorer. So if plans for a jig exist or

someone has a jig and is prepared to make a detailed diagram of it

available then I'd be very grateful. Thanks for the email and I appreciate

everybodys help and suggestions. - Regards, Gary Corino

Carl....sorry about being unclear. Certainly it should have the convenience

of casters,but I meant travelling in the sense that it could travel from

user to user. Granted, if measured by my repair speed, it might not

"travel" often; but if used just for painting, the frequency could be

acceptable. Using pinned and bolted joints instead of welded construction

would ease shipping without loss of rigidity and accuracy e.g.

repeatability. I am still curious about the idea of a common jig for both

120/140/150. Any comments from those who know wheteher this makes sense.

Regards - Klaus Nielsen

Bob, Please send a sketck of the jig to me. - Klaus Nielsen

I worked for the Boeing Airplane spares department for several years before

my retirement. It may be useful to know how they handled the refurbishment

(repair) tooling for airplanes. (There are now about 300 707's still

operating so the disparity may not be too great between 707 problems and XK

challenges.) Tooling was designed by Boeing tooling engineers based on the

expected frequency of repair. Inexpensive tools were made nearly part of

the public domain by releasing the engineering drawings to approved tooling

suppliers and suggesting that these tools be purchased by the operators.

Some of these were shared between operators. Major tools, however, were

built at Boeing and rented to the operators as needed. There was no time

limit, but the operator was required to define the expected period of use

at order entry. When the repair was complete the tool was returned to

Boeing where, without exception, it went through an inspection and repair

operation. There was no charge for this refurbishment service unless there

had been gross abuse by the operator. It is possible that someone could

initiate a jig program based on the Boeing model, but it would have to be

someone with a true love for the XK type and a very long view of return

on investment potential. The management of the program would also require a

pretty professional shop and administrative capability; Welch?, Wray

Schelin? Guy Broad? XK Unlimited? or maybe there is a retired tool

engineer out on the list who could create tool design and make it part of

our public domain? - Carl Orlob

Perhaps someone could post a drawing/photograph on the Tech Library. - Carl

Hanson

Send me the pictures or drawings, I'll post em. - Dick White

My 2 cents on the body jig thread. I would use the body jig only for easy

transport of the body shell when it is off the frame. I would not recommend

any welding of structual components with the body assembly mounted on the

jig. Alignment should be done only on the frame, it would be very difficult

to exactly reproduce all of the frames complexities of support. Final

alignment should be done only on the frame. A inexpensive and dual purpose

body jig can be made with supplies from your local lumber supply

yard,scrap, and junk yard. Build a rectangular frame using 2x6s,attach on

the top edge some 4x4s cross braces , that will pick up the sill support

points, mount some risers to mate with the rear body support points. Brace

the 2x6 frame corners with some plywood. For the axel I have used a solid

rear axel from a front drive car.The junk yards are overflowing with these

axels and you should be able to get one very inexpensively. I like to use

the mini spares mounted to the stripped down axel. You have to weld some

plates onto the axel to attach it to the 2x6 frame. Weld a 2x2 steel

tube(.060"-.085"wall thickness) to the center of the axel and on the other

end ,weld a trailer hitch ball socket. You now have a body jig and a

useable yard trailer (just mount some sideboards and a plywood floor). -

Regards, Wray Schelin

I will be replacing sills and other major parts and would appreciate a copy

of the jig drawing. Photo would also be helpful. - Bob Schilling

To all Jig-lovers: a couple of years ago, I built a rotating jig so I could

"barbecue" my wife's delicate XJ6C that had fully- terminal tinworm. It

worked extremely well, was fully portable on casters and spun the heavy XJ

by 360 deg so you didn't have to "limbo" while sand-blasting and welding.

It was inexpensive to build, involved hardly any welding yet folded down

flat to fit under the bed with both the rowing machine and our large sack

of NOS Lockheed brake cylinders that we're hoarding for our retirement

funds. (Please, no mail begging for wheel cylinders, that was just a

Jagjoke) If I'd built it a few years earlier, and with just minor

modifications, it could have been very useful when we were gutting my XK

140 OTS which had all the usual fender, sill and door post problems but I

must stress that I heartily agree with Wray Schelin's warning about final

body welding being done only back on the car's chassis when the restored

parts are ready for re-assembly, it's the way to go if the chassis is true.

The flimsy XK OTS body MUST have been internaly braced as normal before

being transfered from it's chassis to the "Universal Jag-Jig" and then the

fun can begin. (Or the standing and wondering- "Why did I do this?"). I

never intended to restore another XJ again so I sold the Jag-Jig to a guy

who wanted to modify it to tackle diseased Volvos. ( The Swede Spinner?)

Just so's I don't get into any unwanted debate or misunderstandings on the

construction and safety of the thing, I'm not going to make sketches or

diagrams- I'm not an engineer and I don't want to hear that it's my fault

you didn't agree with my drawings and your XK's fallen on the garage floor

but what I'll do in the near future is to scan a few pictures of the

Jag-Jig supporting approx. 2400 lbs of XJC body and suspensions and offer a

few comments on how it was built and how I see it being modified to handle

a frame-off XK 120/140 OTS with a properly braced body. I'll offer these to

the list administration for inclusion in the "Library" and you're on then

you're own, like I was. Please don't mail me asking for accurate

dimensions, I never kept a record of them and will be offering a

description of the materials list only. If you really want to build one

like this, you'll do it and you'll be popular in the restoration fraternity

in your area. I was and it was a ******* nuisance. Ha!- you won't believe

how some people can do an $X,000 body- restoration job by borrowing and

tying up your equipment but are offended when the subject of a little help

to off-set the cost of making the equipment comes up. You're supposed to

be happy with the case of beer. This thing takes a couple of days to build

and requires access to a good supply of scrap or reasonably priced, rolled

section steel and welded, square steel tubing, it's not for someone who has

no means of drilling lots of 1/2" dia. holes accurately at least by hand

through 1/4" and 5/16" thick steel. You also need a clear floor space of

about 6' 6" x 18' for it just to stand with the body mounted, that doesn't

include room to work at the sides when the body is elevated and in a

horizontal position. 'Nuff said, I'll proceed with the pisc ASAP so TTFN -

John Morgan

To all wishing to barbeque this spring, at

http://www.jag-lovers.org/xk-lovers/library/drenzek.html are pictures of the

rotisserie which David Drenzek built for his 150 OTS. There aren't any

dimensions or instuctions but perhaps the pictures will provide some ideas.

As for TTFN I'm surprised no one has mentioned Winnie the Pooh. Tigger

(that's correctly spelled with two guh's) frequently says TTFN as he

bounces off screen. - Regards, Dick White

Many thanks to Bob Lockas for the jig drawings. It looks like a very

straight forward way to handle the OTS body off of the frame. I am just

getting to the point of worrying through how to accomplish that manuver so

the plans were very timely. My 120 does have a badly damaged front wing. Is

it a good idea to remove the damaged wing before removing the body? The

damage is to the front third of the wing and does not seem to have affected

the mounting point near the frame. I have had some advice to remove both

wings for access to the posts. Will this make for a difficult fit up with

the bonnet on reassembly? Any advice or comments are appreciated. - Bob

Schilling, OTS 660775

|